Fuel & Core Components Advisory Services

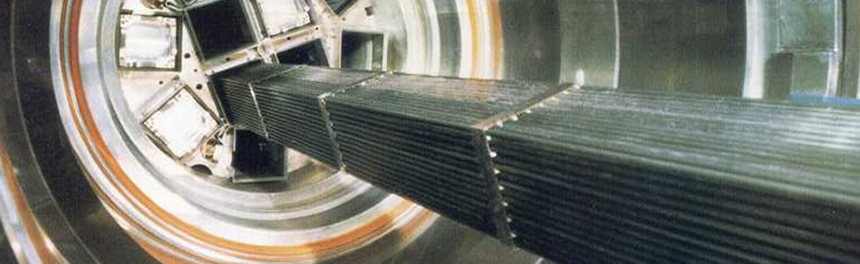

NAC International fuel and core components consulting provides customers with valuable technical advice and analyses to improve product designs, internal systems and business performance.

NAC’s also provides technical and quality assurance oversight in the manufacture of nuclear fuel and components based on its extensive experience in the United States, Europe, The Middle East, and Asia. NAC experts can provide vendor quality assurance system audits, manufacturing process qualification audits, performance-based manufacturing oversight, and training of customer personnel.

NAC’s design review and analysis includes an evaluation of a fuel or component’s likely performance under operating and accident conditions. Such analyses are available in support of procurement activity, supplier transition, or the introduction of a new design, design feature or manufacturing process by a supplier.

Procurement Services and Support

Leading utilities rely on NAC for fuel fabrication procurement support, which includes fabrication market analysis; request for proposal (RFP) development; technical, economic and commercial bid evaluations; drafting of bid specifications and fuel supply contracts; support of contract negotiations; and assistance in transitions between fuel vendors.NAC’s also provides technical and quality assurance oversight in the manufacture of nuclear fuel and components based on its extensive experience in the United States, Europe, The Middle East, and Asia. NAC experts can provide vendor quality assurance system audits, manufacturing process qualification audits, performance-based manufacturing oversight, and training of customer personnel.

Design Review and Analysis

NAC experts offer nuclear fuel and core component design review and analysis, providing independent assessments of fuel and reactor core component designs, newly introduced design features, and new materials.NAC’s design review and analysis includes an evaluation of a fuel or component’s likely performance under operating and accident conditions. Such analyses are available in support of procurement activity, supplier transition, or the introduction of a new design, design feature or manufacturing process by a supplier.

Dave Culp

Dave Culp